Overwhelmed with the seemingly endless types of packaging materials to choose from? Get the fast facts from PPT.

Many brands are concerned with minimizing their negative environmental impact. As brands work to find a balance between sustainability and customer satisfaction as it applies to product freshness, safety, and convenience, sustainable flexible packaging has come to the forefront as a surprising solution.

Flexible Packaging: The Better Environmental Choice

As it turns out, sustainability and plastic flexible packaging are not exclusive. In fact, life cycle assessments of various packaging types performed by the Flexible Packaging Association demonstrate that flexible packaging has preferable environmental attributes for carbon impact, fossil fuel usage, water usage, product-to-package ratio, and material to landfill.

The lifecycle assessments compare the environmental impact of packaging throughout its lifecycle for various product categories. Below are the results for coffee and laundry detergent pods, for example.

| Product | Packaging Format | Fossil Fuel Consumption (MJ-Equiv) | Green House Gas Emissions (kg-CO2 equiv) | Water Consumption (l) | Product-to Package ratio and percent wt. | Pkg Landfilled (g)/1000 kg product |

| Coffee | Standup flexible pouch | 6,654 | 353 | 1011 | 24.8:1 96.1%:3.9% | 40,294 |

| Steel can | 36,809 (+453%) | 2763 (+683%) |

17,238 (+1605%) | 2.0:1 67.1%:32.9% | 163,122 (+304%) | |

| Plastic (HDPE) canister | 41,130 (+518%) | 1678

(+376%) |

3,164 (+213%) | 4.8:1 82.8%:17.2% | 142,063 (+252%) | |

| Laundry Detergent Pods | Stand-up Pouch w zipper | 76.73 | 3.10 | 5.00 | 47.2:1 97.9%:2.1% | 21,209 |

| Rigid PET Container | 463.68 (+504%) | 25.60

(+726%) |

37.98 (+660%) | 8.5:1 89.4%:10.6% | % 82,604 (+289%) |

These two examples show that changing to flexible pouches can reduce fossil fuel consumption, greenhouse gas emissions, and water consumption. In addition, the higher product to packaging ratio reduces the impact on shipping as the weight reduction and small size increase the number of products that can be shipped per truckload, reducing fuels consumption and truck emissions.

Don’t Lose Gains Made From Using Sustainable Flexible Packaging

If you are already using flexible packaging or considering a switch, there are things you can do to ensure the environmental gains are not reduced or wasted. You can further contribute by choosing film and packaging carefully.

Understand Your Equipment

It is important that you understand the temperatures and dwell times needed to produce a quality seal. Use films that are engineered to run at your filling equipment’s optimal speed and temperature. If not, you may reduce efficiencies, use more resources, or have poor sealing, leading to higher scrap if found right away or product waste and customer dissatisfaction if a seal fails after leaving your facility.

Choose Quality Films and Printing

Cutting corners seldom works out in the long run. Low-quality films can often stretch or wrinkle, increasing your scrap rate. Poorly printed roll stock will increase your scrap rate if you have to cut off sections that aren’t printed well.

Work with an Experienced Engineering Team

There is no one-size-fits-all approach. If you are purchasing roll stock or flexible packaging, work with an engineering team that can evaluate the best solutions specific to your products and filling equipment. If you need oxygen, moisture, or UV protection, an experienced engineering team can assure that the film or packaging will protect the product through its intended shelf life. Using the right film and packaging not only reduces scrap within your facility but also reduces food waste because food products stay fresher longer.

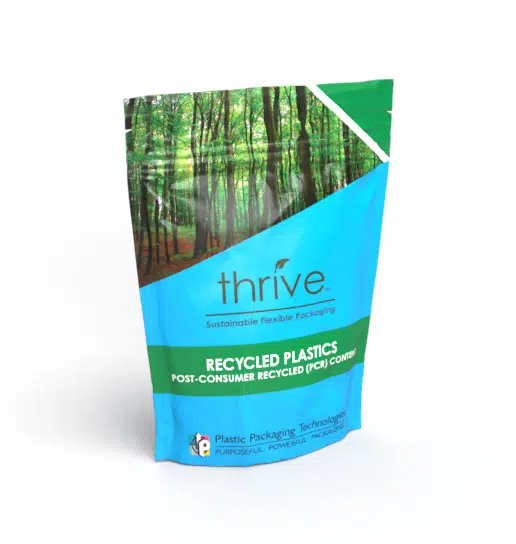

Choose Eco-friendly Materials

Choosing films and packaging that the consumer can recycle, are made from post-consumer recycled content, or are made from renewable resources can reduce your carbon footprint. The Thrive™ line of roll stock and pouches provides eco-friendly packaging solutions in a wide range of materials.

Choose an Environmentally Conscious Partner

At Plastic Packaging Technologies, we have the same concerns as you about protecting our environment. Not only do we offer sustainable packaging solutions, but we also have sustainability policies that apply to our own processes.

We invest in equipment that generates low volumes of scrap and maximizes raw materials, including reducing ink and solvent waste. Additionally, we have a sustainability goal of zero-landfill waste that we strive to meet through maximizing recycling and employing an alternate waste program that incinerates waste for energy creation. We also choose vendors that have their own sustainability objectives, ensuring the environmental impact is lessened throughout the supply chain.

Our product development team creates lightweight packaging and high-quality films to assist our customers with waste reduction when replacing resource-heavy rigid packaging. This includes reducing the film gauge to generate less waste while maintaining product protection. Our engineers will work onsite with our customers to ensure that the packaging or roll stock will work with their equipment and generate minimal scrap.

Our color management system prevents color rejections and ensures your colors are vibrant and consistent from run to run. We have defect systems in place, such as web cameras that can pick up defects quickly, to reduce non-conforming scrap generation.

Contact us to discuss how sustainable flexible packaging and roll stock solutions can help you.