Flexible packaging design trends for 2023 will include sustainable, multifunctional, innovative, and e-commerce-friendly packaging with impactful colors. Explore more here.

Pros and Cons of the Most Common Packaging Types

When it comes to selecting the right packaging for your products, it’s important to consider the entire supply chain process. Your packaging doesn’t just need to get your product into the hands of consumers. As customers become more eco-conscious, you must also take into account the packaging’s impact on the environment — both before and after consumption. Let’s look at the most common types of packaging materials and find what’s right for your business.

Rigid Plastic Packaging

Rigid plastic packaging is more durable and can handle more pressure than other types of packaging materials. This ultimately results in less damaged product and customer returns. It’s highly customizable, as it’s able to achieve a variety of shapes. You can also choose from various substrates to fit your exact needs, including PET and HDPE, for example.

However, the cons of rigid plastic packaging are not to be ignored. It’s typically more expensive to produce than other types of packaging materials, and can have a higher carbon footprint. It can also result in higher shipping costs, as it takes up more space than other materials that can lay flat. Perhaps the most important consideration is its contribution to pollution. If not recycled, it can take up space in landfills or other undesirable areas.

Folding Cartons

Unlike rigid plastic packaging, folding cartons are cost-effective. They’re also a great, lightweight option for protecting products from damage during transit. Additionally, they can be made from recycled materials, reducing the impact on the environment.

The downfall of folding cartons is their inability to handle moisture. Water and other products may saturate the cardboard, damaging the contents. Also, they may become deformed if exposed to extreme pressure or when stacked.

Flexible Packaging

Flexible packaging combines all the pros of the aforementioned packaging materials, with none of the cons. Flexible packaging material refers to material that’s flexible or easily yielding that, when filled or closed, can be readily changed in shape. Rollstock is a common option for flexible packaging, due to its durability and ability to be printed with bright, gleaming graphics. It can be formed into a variety of pouches, depending on the need of the product being packaged.

Rollstock and other flexible packaging materials are low-cost, lightweight, and a great barrier against moisture. They’re also heat sealable to prevent leakage. When unfilled, they take up little space, which can cut down on your storage and transportation costs.

The only downside associated with flexible packaging is that it’s typically made from plastic, which comes from a nonrenewable resource. However, in recent years, new technology has arisen to provide sustainable, renewable flexible packaging.

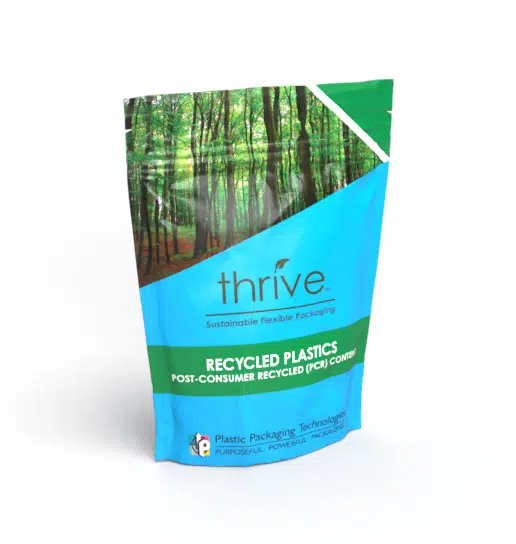

Made from renewable materials like corn, sugarcane, or other recycled packaging, Thrive™ material is lightweight, heat sealable, and a fantastic barrier against moisture. It can be printed with bright, eye-catching graphics and shaped into a variety of pouch options. With all these advantages of flexible packaging and rising consumer demand for sustainable business practices, Thrive™ might be the best option for your brand.

Let Us Help You Find the Perfect Packaging Option

Plastic Packaging Technologies is committed to enriching people’s lives and the products they use through purposeful, powerful flexible packaging. When you’re looking to revamp and improve your packaging, we’ll be there to help guide you. Our dedicated Innovation and Technical Teams partner with our clients to offer ideas and guidance to ensure their packaging exceeds their goals in terms of function, performance, and presence.

As an industry leader in laminated and surface-printed rollstock, Plastic Packaging Technologies offers a wide selection of flexible packaging formats for various markets. We focus on providing the highest quality flexible packaging solutions by utilizing industry-leading machinery, equipment, and technology.

We hold numerous certifications to hold our packaging products to high standards. We maintain ISO 9001:2015, SQF Edition 9, 5S LEAN, and GMI certifications. When you work with Plastic Packaging Technologies, you’ll know you’re receiving the best quality packaging possible, along with unparalleled customer service. We offer fast and responsive service from a team of experienced industry professionals that provide in-depth knowledge and expertise.

Let’s Get Started on Your Flexible Packaging

Ready to learn more about flexible packaging? Get in contact with one of our helpful team members here.